Overview

A soundproof generator cabin is designed to isolate noise, protect the generator from environmental conditions, and provide safe operation and maintenance. It is engineered for optimal acoustic insulation, thermal management, vibration isolation, and efficient airflow.

1. Cabin Structure: Components & Features

Wall Panels

High-density rock wool sandwich panels for acoustic absorption, thermal insulation, and fire resistance. Includes optional internal acoustic lining and ventilation ducts with acoustic baffles.

Flooring System

Galvanized steel base frame with vibration isolation. Features anti-vibration mounts, insulated steel floor with high load-bearing capacity, and is lined with rubber mats or composite acoustic boards.

Roof Panel

Sandwich panels with rock wool core. Options include sloped or flat roof design, rainwater gutters, lift hooks, and integrated sound traps for exhaust vents.

Doors & Access Panels

Single or double doors with EPDM rubber acoustic seals and heavy-duty hinges; includes lockable maintenance hatches.

Ventilation System

Inlet and outlet louvers equipped with internal acoustic baffles; optional motorized dampers and exhaust silencers available.

Lighting & Electrical

Integrated LED lighting, maintenance lights, and control box for ventilation, alarms, and safety.

Optional Features

May include fire suppression, remote monitoring sensors, and automatic exhaust fan control.

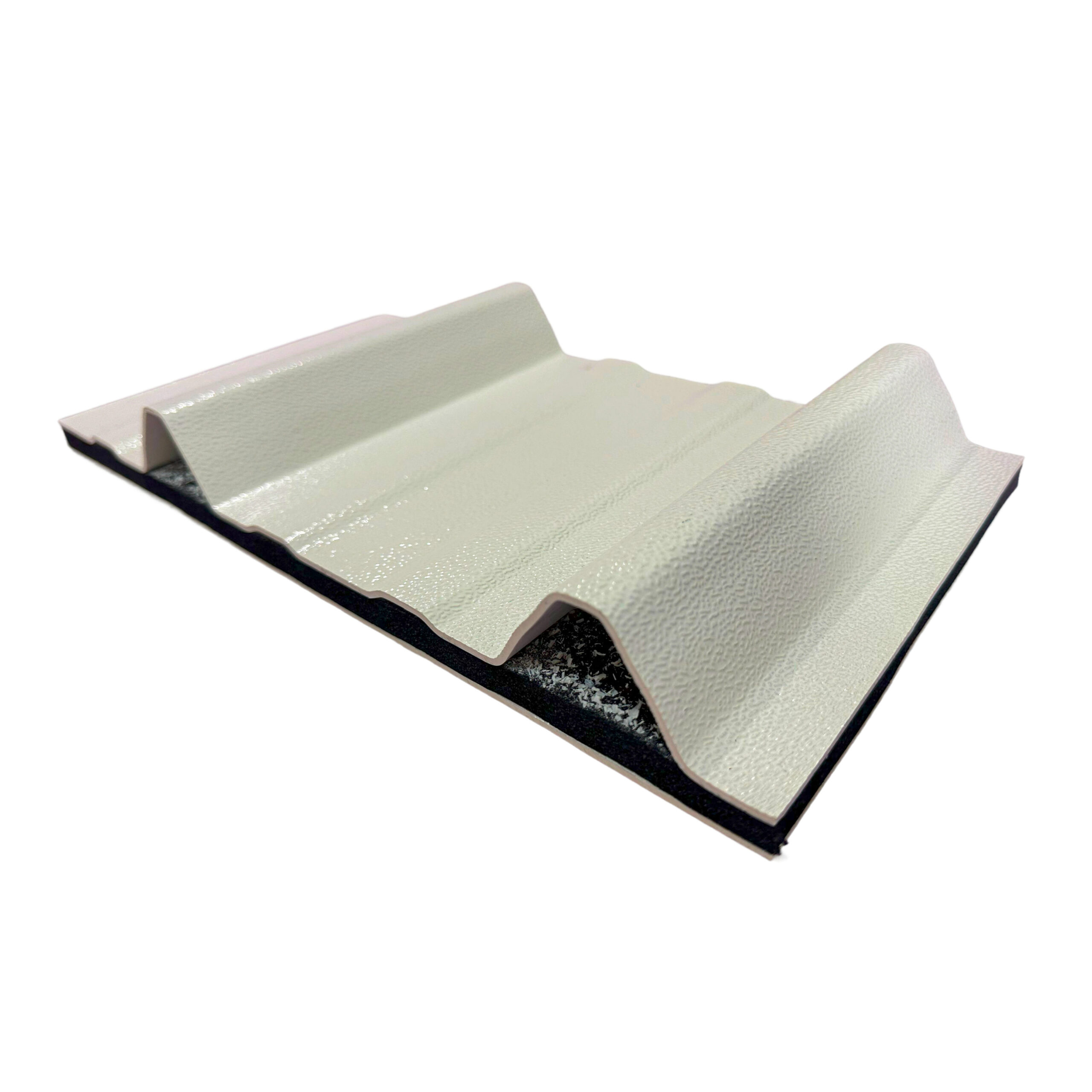

2. Micronized Sandwich Panel Specifications

Recommended Panel Type: Rock Wool Core Micronized Sandwich Panel (50–100mm thick).

Panel Composition:

– Outer Skin: Micronized UPVC sheet for weather protection and strength.

– Core: Rock wool (60–120 kg/m³) for acoustic and thermal insulation plus fireproofing.

– Inner Skin: Micronized UPVC sheet for enhanced acoustics and durability.

Dimensions: Thickness: 50mm (min), ideally 75–100mm; Standard width: 1000mm; Custom length.

3. Acoustic Performance

For a 100mm Rock Wool Panel: Sound reduction up to 35–45 dB (RW rating), non-combustible fire rating (EN 13501 A1), and thermal conductivity of 0.035–0.040 W/m·K.

4. Benefits of Using Rock Wool Sandwich Panels

- High soundproofing capacity

- Fire resistance (Class A1)

- Effective thermal insulation

- Durable and weather-resistant

- Easy installation, disassembly, and relocation

- Supports HVAC and cable routing integration

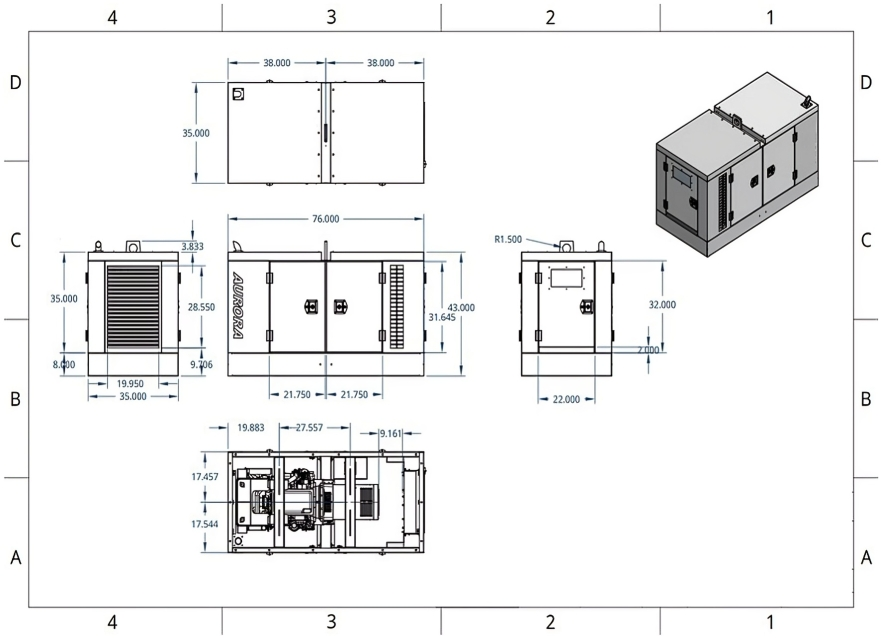

5. Example Cabin Layout

Typical dimensions: 3m x 4m x 2.5m (W x L x H), depending on the generator size. Wall panels are 100mm thick rock wool with a PPGI surface; the floor is a steel plate with anti-vibration pads; the roof is inclined with a gutter system; double-leaf, acoustically sealed doors; and a well-planned ventilation system.

6. Installation Notes

• Ensure the foundation is flat and vibration isolated.

• Install panels onto a steel base frame; add roof panels last for top access.

• Design airflow paths to avoid direct sound leaks by using acoustic baffles.

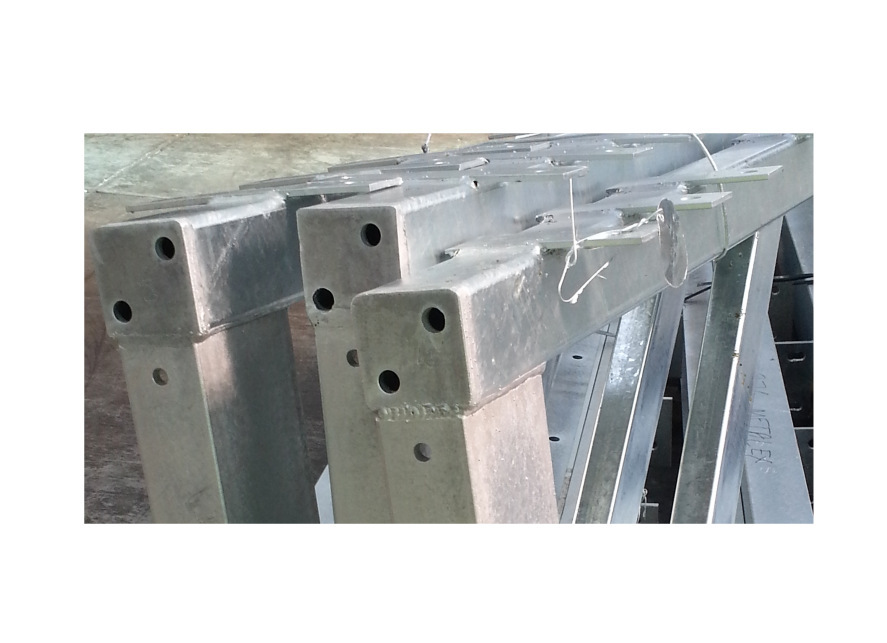

Steel Frame Specification

The steel frame is critical for structural integrity and vibration isolation:

• Steel Type: Hot-dip galvanized (Q235 or Q345 grade).

• Base Frame: 100×50 mm rectangular tube, 3–5 mm wall thickness.

• Columns & Beams: 80×40 mm or 100×50 mm RHS, 2.5–3 mm thickness.

• Roof Support: C-channels or angles, 2–3 mm thickness.

• Surface Finish: Galvanized or powder-coated for corrosion resistance.