Portal steel structures provide expansive, column-free interior spaces ideal for warehouses, workshops, and commercial facilities. Engineered for durability and rapid assembly, portal steel structures ensure efficient load distribution and excellent performance under challenging weather conditions. Whether you’re expanding your operations or designing a new facility, these structures deliver the strength and flexibility required for contemporary building needs.

Industrial Steel Buildings

WAREHOUSES

Woodtech storage building

FACTORIES

Textiles manufacturing

DATA CENTERS

cyber security company

AUTOMOTIVE

Mega cars showroom

Agricultural Steel Buildings

STORAGE UNITS

Corn farm warehouse

STABLES

Horse stable farm

EQUIPMENT UNITS

Equipment storage area

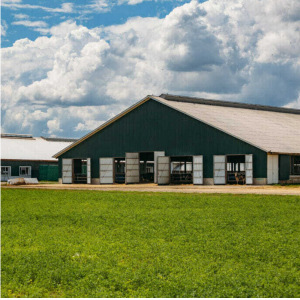

BARNS

Cow barn area

Commercial Steel Buildings

COFFEE SHOPS

Coffeehouse design structure

RESTURANTS

Indoor & outdoor Dine-in

RETAIL SHOPS

Sneakers outlet shop

MEGA MARKETS

Mega market Structure

Residential Steel Buildings

HOUSES

Steel house building

RESIDENTIAL HALL

University dorms

LIVING QUARTER

Workers living quarter

MOTELS

Motel steel structure

PROJECTS

RESIDENTIAL

Villa Structure

STORE

Clothes shop Structure

BUSINESS

Data Center Structure

INDUSTRIAL

Mega cars showroom

Portal Steel Structure Summary

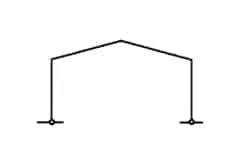

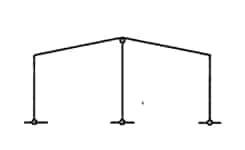

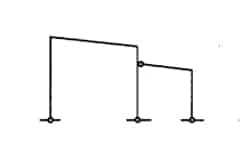

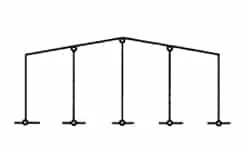

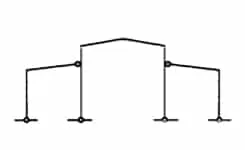

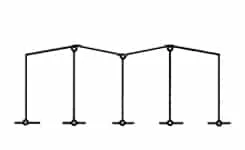

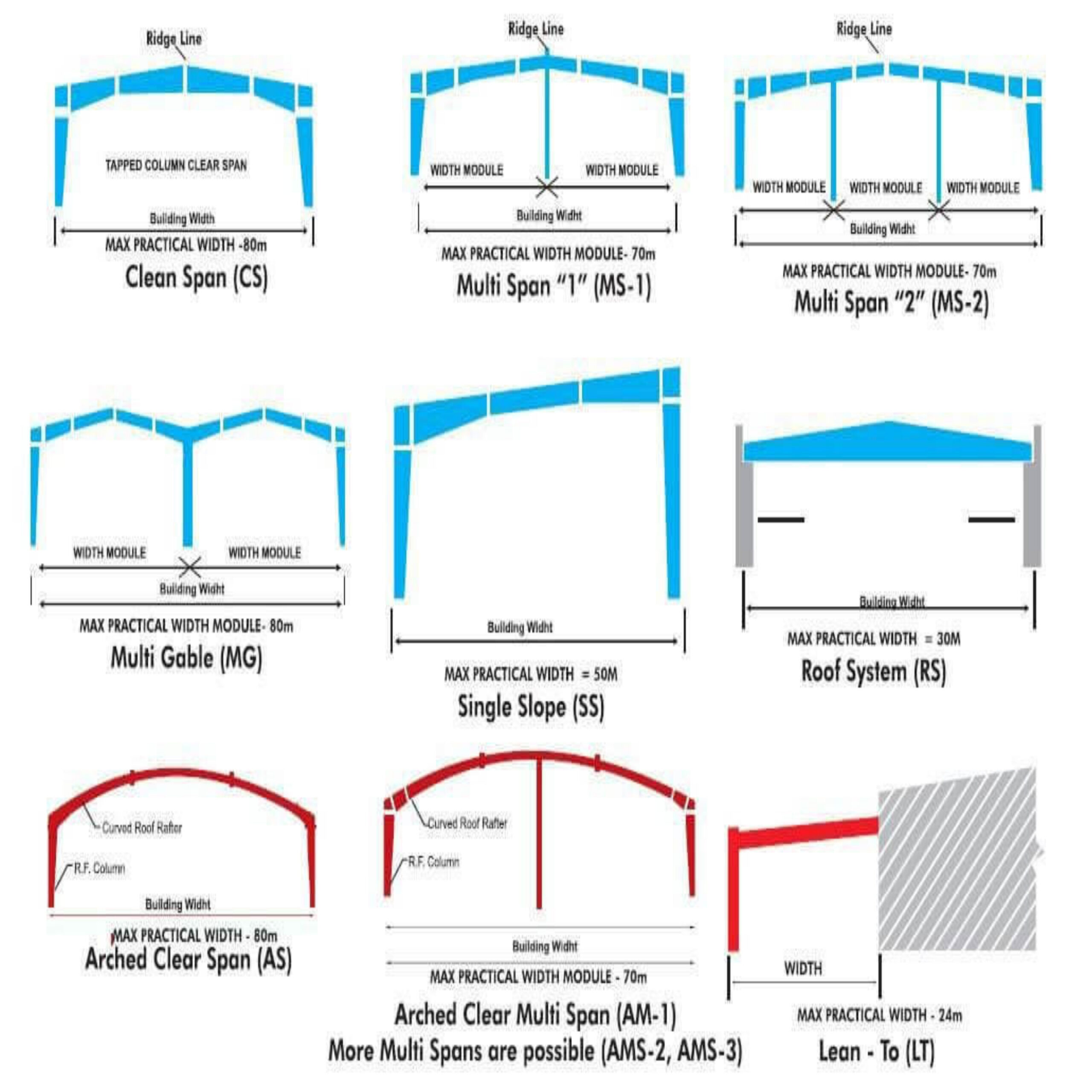

Generally, when laying the portal steel structure building, it should follow the principle of “length greater than the width”, which can reduce the amount of steel for the portal frame. At the same time can also reduce the wind load between the column support, thereby reducing the steel of the support system. For example, the size of the portal frame building is 60x50m, when the plant is arranged, 60m should be used as the length direction and 50m as the span direction.

We will determine economic and reasonable spans based on the height of the house, and satisfying production technology and use functions. In general, when the height and the load are certain, if the span is increased, the amount of steel for the portal frame will not increase significantly. But it saves space, reduces the basic cost, and makes the comprehensive benefits more considerable. It is found by a large number of calculations that when the span exceeds 48m, it is suitable for using multiple spans. Its steel volume saves more than 40% compared to a single-span portal frame. Therefore, when designing the portal steel structure building, a more economical span should be selected according to specific requirements. Brinovo will provide more options for you.

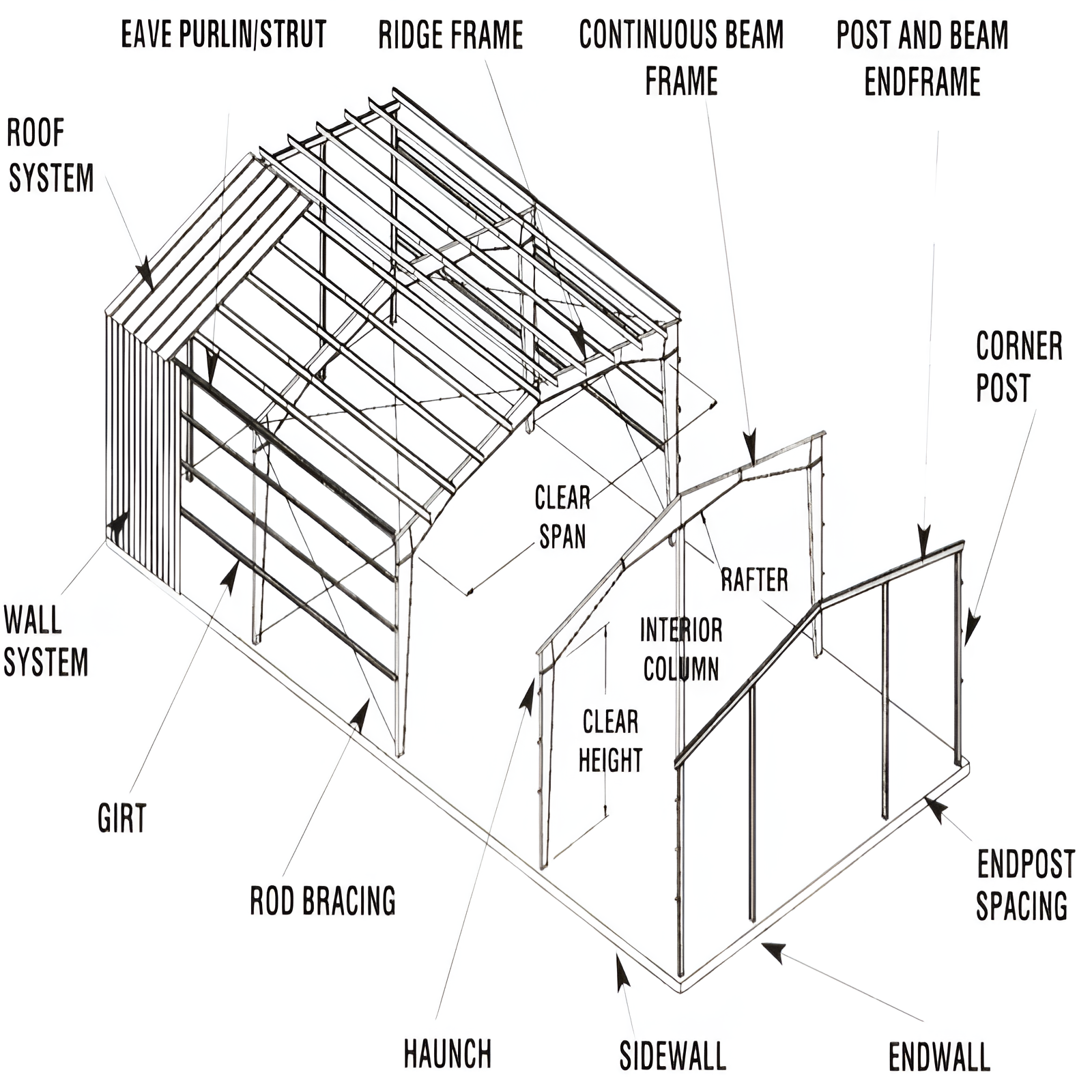

The technology economy compares that the most economical portal steel structure building column spacing under standard load is 8-9m. When it exceeds 9m, the amount of steel in the roof bars and the wall frame system increases too much, and the comprehensive cost is not economical. The standard load here refers to: the roof is 0.3kn/㎡, and the basic wind pressure is 0.5kn/㎡. When the load is greater, the economic column distance should be reduced accordingly. For factories with more than 10 tons, the economic column distance should be 6-7m. Brinovo will perform scientific calculations based on the location of your project to ensure the security and firmness of the portal steel structure building.

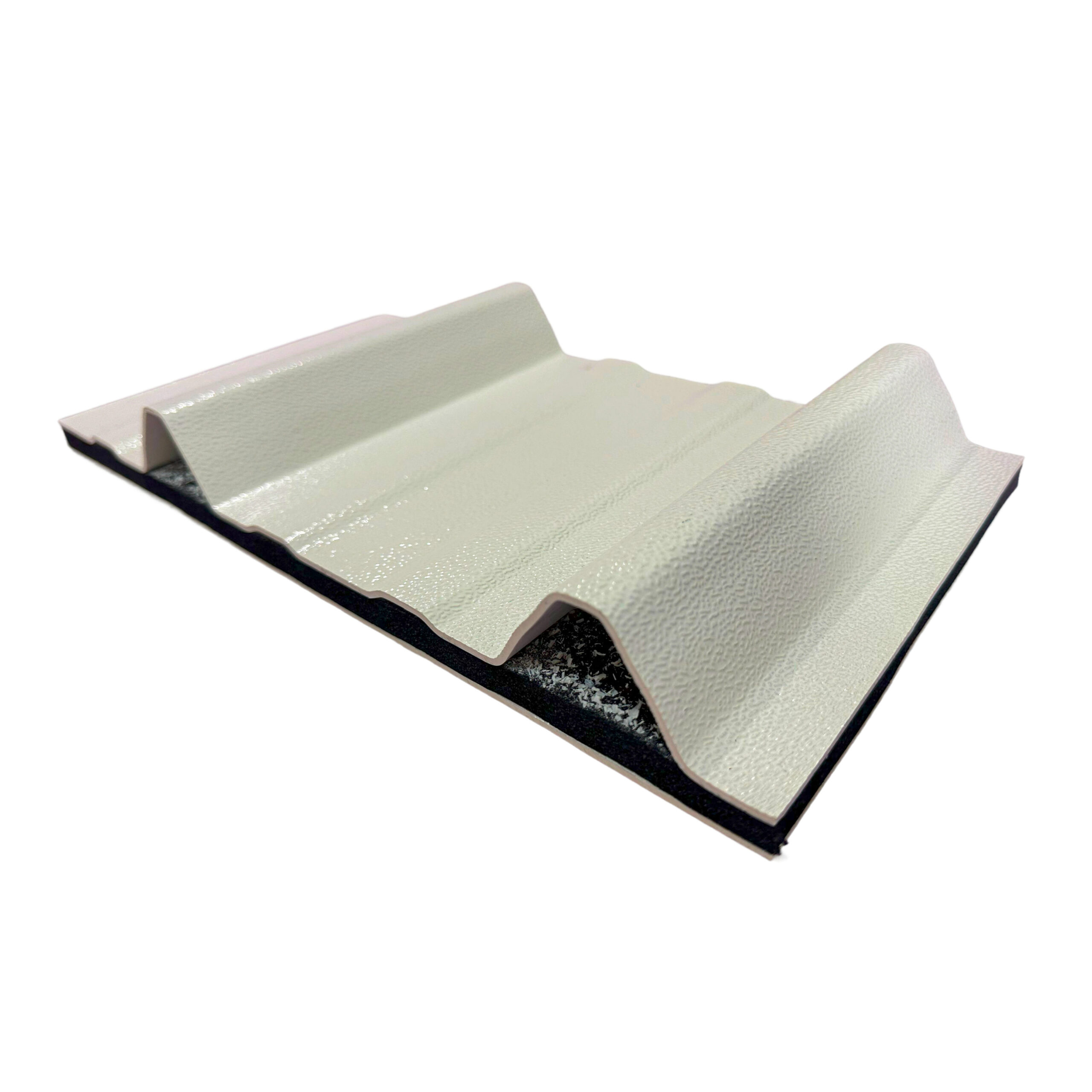

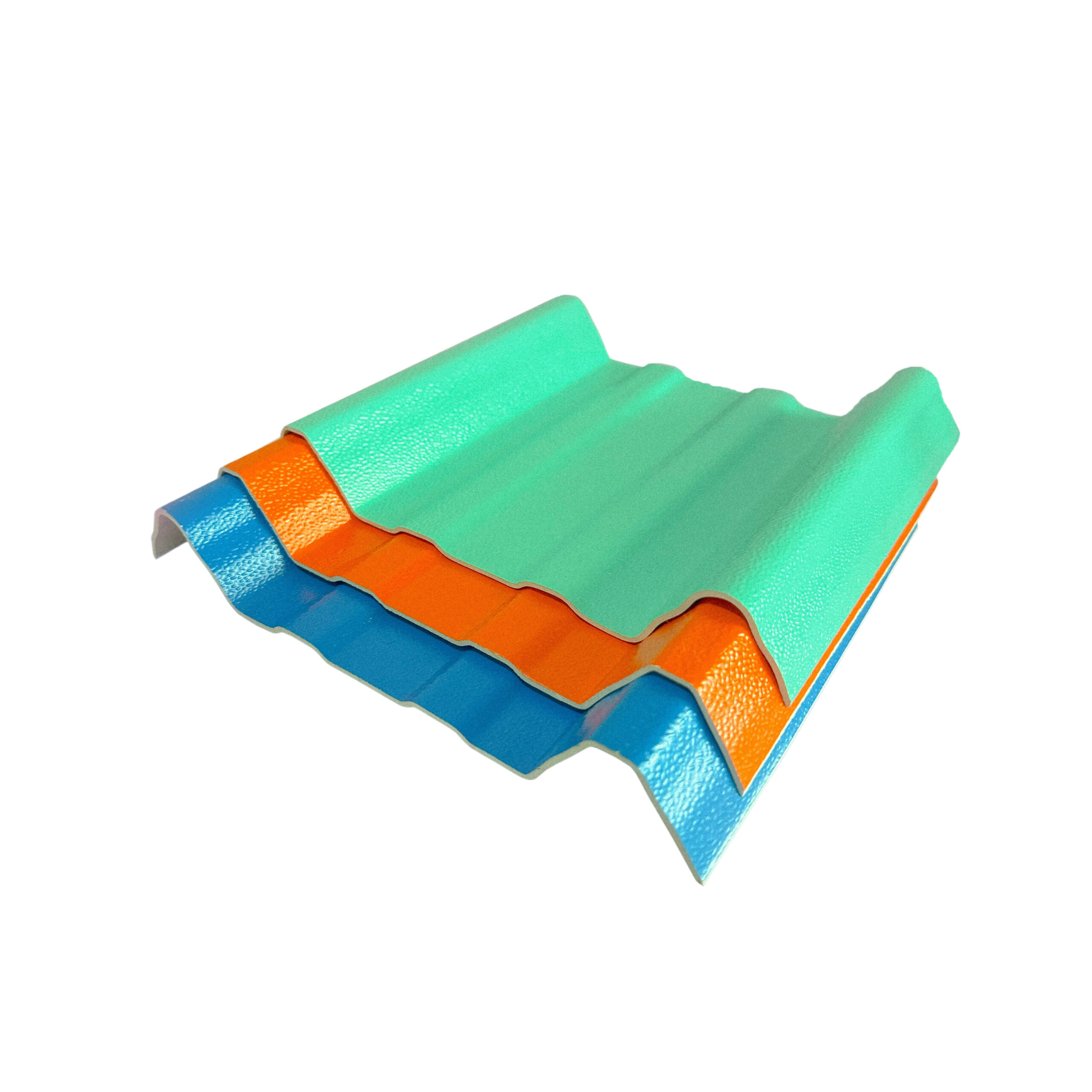

Micronized Roofing & Walling Options

Micronized UPVC sheets offer a lightweight, durable, and energy-efficient roofing solution for portal steel structure buildings. With excellent thermal insulation and weather resistance, they reduce operational costs while enhancing the building’s modern aesthetic.

Micronized Sandwich Panels provide a high-performance roofing solution that excels in thermal insulation, fire resistance, and structural strength. Engineered with two metal faces bonded to an insulating core, they offer superior energy efficiency and durability, ideal for modern portal steel structure buildings.Double layer sandwich panels are highly effective for wall material. Comprising two outer Micronized UPVC sheets bonded to an insulating core, they provide thermal and acoustic insulation. This design reduces energy consumption by minimizing heat transfer and enhances fire resistance and durability.